Máquina de instalação de trilhos e pinos de drywall KINGREAL para a Arábia Saudita

2024-09-10 13:43KINGREAL Drywall Stud And Track Machine To Saudi Arabia

KINGREAL has been successfully transported the High Speed CU Channel Roll Forming Machine to the Saudi Arabia.

According to the Saudi Arabia customer‘s demand for production efficiency, KINGREAL has customized a high-speed drywall stud and track roll forming machine with a speed of up to 100M/MIN.

From drawing confirmation, machine manufacturing to final packing and delivery, KINGREAL makes sure to contact the customer at every step of the way to let them know the production progress at the first time.

As a result, the customer in the Saudi Arabia gave high praise to KINGREAL and expressed their expectation for the next cooperation.

Highlights of KINGREAL drywall profile machine

Automatic Packaging System: Improved Efficiency

One of the outstanding features of the KINGREAL gypsum board channel machine is its integrated automatic packaging system. Once the studs and tracks are produced on the production line, they are fed directly into the automatic packaging unit without manual handling. This system significantly improves efficiency by eliminating the need for workers to manually pack the finished products.

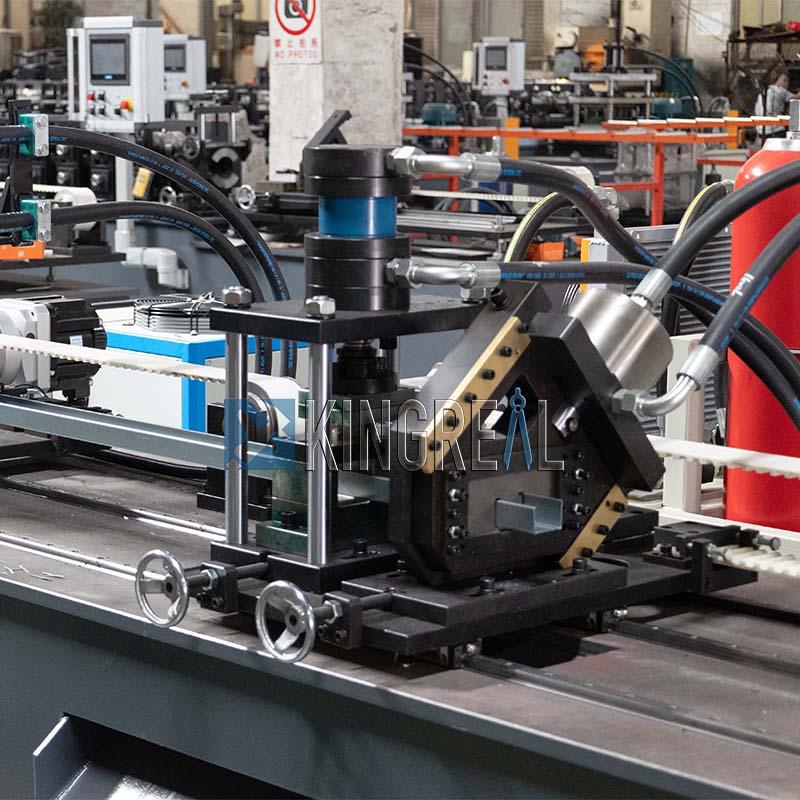

Flying Shears and Flying Punches: Continuous Cutting, Time Saving

Another impressive feature of the KINGREAL drywall stud and track machine is its use of flying shears and flying punches. These innovations enable the machine to perform continuous cutting without stopping the production line. Typically, in many traditional machines, the cutting and punching processes require the machine to stop, resulting in downtime and reducing overall production efficiency.

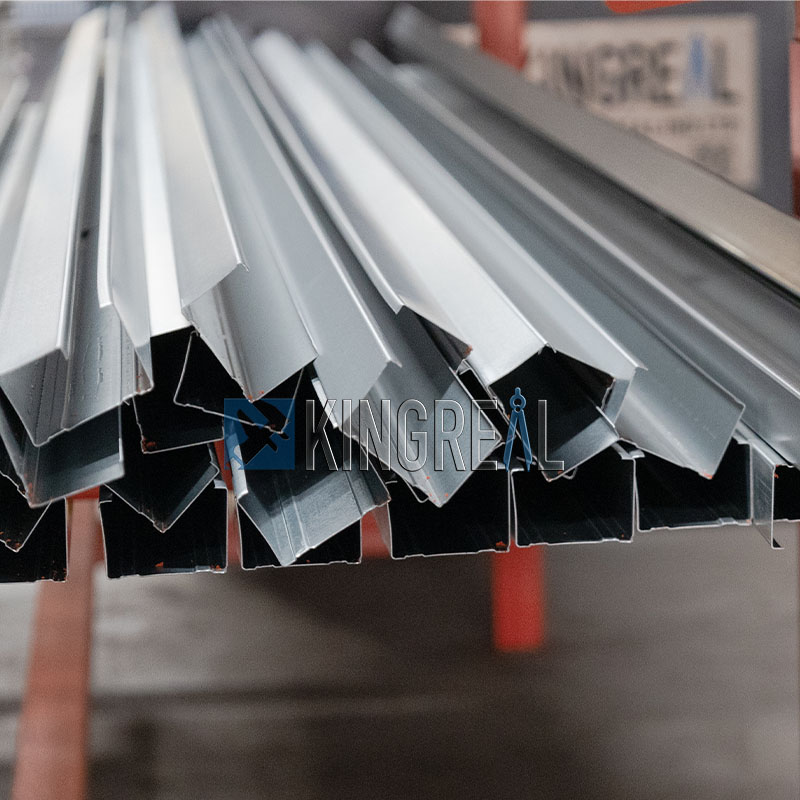

Production Flexibility: Produce Multiple Product Sizes

One of the main competitive advantages of KINGREAL's gypsum board channel machine is its versatility. The machine is designed to produce a variety of sizes of drywall studs and tracks, including different widths and heights, on a single production line. This flexibility is achieved through a roll forming machine that can automatically adjust the width and narrowness.

The ability to switch between different product sizes without requiring major renovations or changes to production lines is a major advantage for manufacturers who need to respond to varying customer demands or market trends. This capability is especially beneficial in areas where projects range from small homes to large commercial buildings, each requiring different sized studs and tracks.